Download Free Software Inductive Transducers Pdf Editor

The Inductive Wear Debris Sensor is a relatively new invention that is increasingly being used for the detection of incipient machinery damage or failures by sensing metallic debris in lubrication systems. This type of sensor is typically used in-line and has a superior particle size detection range compared to traditional techniques such as the ubiquitous spectrometric oil analysis. There is, however, very little in the literature regarding the application and interpretation of data arising from this type of sensor.

Unlike other condition monitoring sensors, no data will be generated by an Inductive Wear Debris Sensor in an ideal system; however, in real applications it is necessary to discriminate between occasional particles unrelated to a failure and incipient failure particles. Inductive Wear Debris Sensor data could be misinterpreted if a simple cumulative count limit was applied to the data. A short-term rate of particle generation is sometimes used as an alternative; however, it too can be misleading with short succession particles producing high instantaneous rates possibly causing false alarms. The purpose of this work was to develop a robust metric (or group of metrics) that when applied to Inductive Wear Debris Sensor data would reliably identify a failure event and exclude non-failure related particles. The Health Indicator described herein consists of three subordinate Condition Indices that collectively are shown to reliably detect the onset of rolling contact fatigue.

The metrics have been applied to bearing test rig data (seeded fault) and data obtained from a non-seeded fault test of a complex helicopter gearbox. Condition monitoring of wind turbines, Palo Alto, CA: Electric Power Research Institute, 2006.

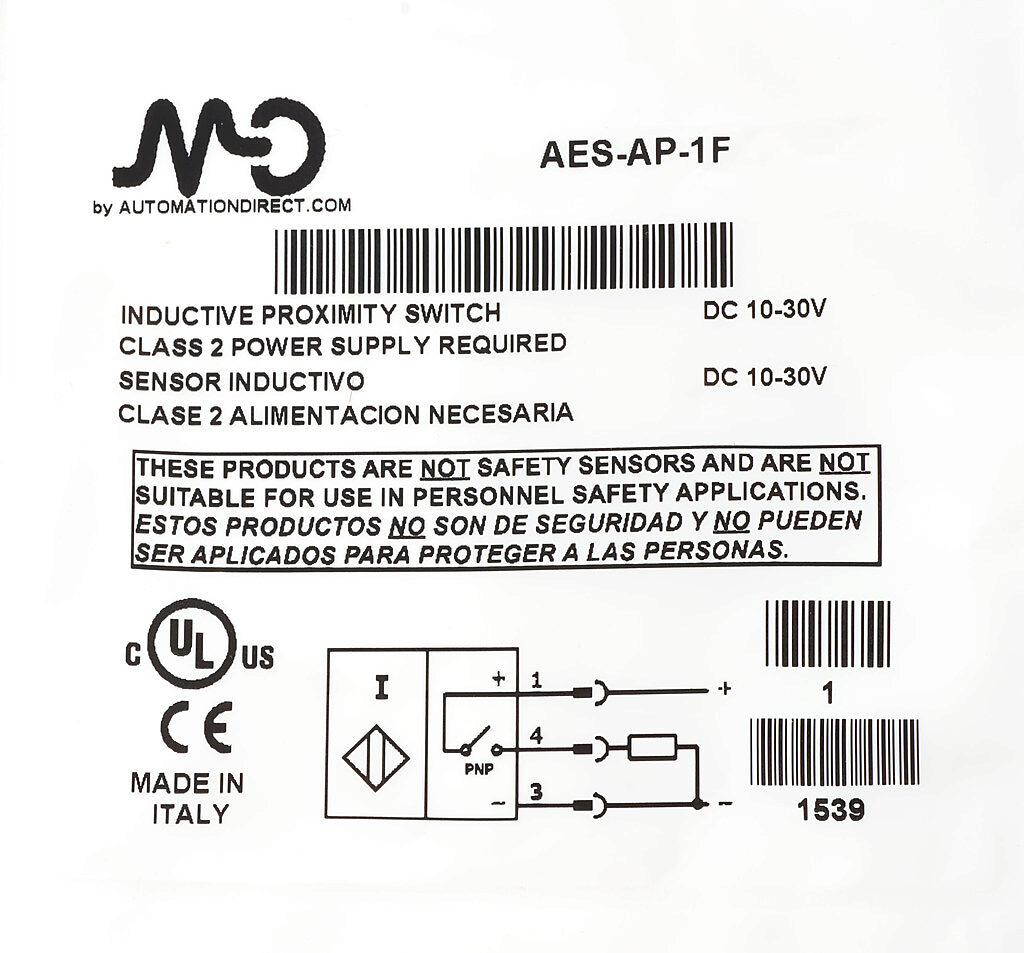

Inductive proximity sensor, tubular, 18mm diameter x 50mm body, nickel-plated brass housing, PNP, N.O. AK1-AP-1A Compliance Information. Customers who bought a AK1-AP-1A also purchased the following items. Look for the PDF file in the library download for documentation. Tree automata and tree transducers are used in a wide range of applications in software. Free function-blocks, available for download also make it easy for 787-16XX modules to communicate.

Miller JL and Kitaljevich D. In-line oil debris monitor for aircraft engine condition assessment. In: IEEE Aerospace Conference Proceedings, Big Sky, MT USA, Vol 6, 2000, pp.49–56. Toms, AM, Cassidy, K. Filter debris analysis for aircraft engine and gearbox health management.

J Fail Analysis Prevent 2008; 8: 183– 187., 4. Becker, AJ, Abanteriba, S, Forrester, D. Determining inductive sensor wear debris limits for rolling contact fatigue of bearings. Proceedings of the Institution of Mechanical Engineers, Part J: J Eng Tribol 2015; 226(6): 698– 711. DOI: 10.11114559997., 5.

Fluid film lubrication, Cambridge, MA: Cambridge University Press, 2010., 6. Sadeghi, F, Jalalahmadi, B, Slack, T. Review rolling contact fatigue. J Tribol 2009; 131: 41403– 41415., 7. Aerospace bearing life rating experience. American Society of Mechanical Engineers (Paper), San Francisco, CA, USA: ASME, 1996. On the impact of fine filtration on spectrometric oil analysis and inductive wear debris sensors.

Proceedings of the Institution of Mechanical Engineers, Part J: J Eng Tribol 2016; 230: 78– 85. DOI: 10.11115592917., 9. Rolling bearing analysis, USA: John Wiley & Sons, 1966. Zaretsky, EV. Rolling bearing life prediction, theory and application, Cleveland, OH: NASA, 2013. Flanagan, IM, Jordan, JR, Whittington, HW.

An inductive method for estimating the composition and size of metal particles. Measure Sci Technol 1990; 1: 381– 384.

Visualization of magnetic structures of a linear encoder (Recorded with MagView). A linear encoder is a sensor, or readhead paired with a scale that encodes position.

The sensor reads the scale in order to convert the encoded position into an or, which can then be decoded into position by a digital readout (DRO) or motion controller. The encoder can be either incremental or absolute. Motion can be determined by change in position over time. Linear encoder technologies include optical, magnetic, inductive, capacitive and.

Optical technologies include shadow, self imaging and. Linear encoders are used in metrology instruments, motion systems and high precision machining tools ranging from digital calipers and to stages, CNC Mills, manufacturing gantry tables and semiconductor steppers. Contents.

Physical principle Linear encoders are transducers that exploit many different physical properties in order to encode position: Scale/reference based Optical Optical linear encoders dominate the high resolution market and may employ shuttering/, or principles. Optical encoders are the most accurate of the standard styles of encoders, and the most commonly used in industrial automation applications. When specifying an optical encoder, it’s important that the encoder has extra protection built in to prevent contamination from dust, vibration and other conditions common to industrial environments. Typical incremental scale periods vary from hundreds of micrometers down to sub-micrometer. Can provide resolutions as fine as a nanometre. Optical Linear Encoder mounted on Mitutoyo Light sources used include infrared, visible LEDs, miniature light-bulbs and.

Magnetic Magnetic linear encoders employ either active (magnetized) or passive (variable reluctance) scales and position may be sensed using sense-coils, or readheads. With coarser scale periods than optical encoders (typically a few hundred micrometers to several millimeters) resolutions in the order of a micrometer are the norm.

Capacitive Capacitive linear encoders work by sensing the capacitance between a reader and scale. Typical applications are digital calipers.

One of the disadvantages is the sensitivity to uneven dirt, which can locally change the. Inductive Inductive technology is robust to contaminants, allowing calipers and other measurement tools that are coolant-proof. A well known application of the inductive measuring principle is the Inductosyn. Eddy current US Patent 3820110, 'Eddy current type digital encoder and position reference', gives an example of this type of encoder, which uses a scale coded with high and low permeability, non-magnetic materials, which is detected and decoded by monitoring changes in inductance of an AC circuit that includes an inductive coil sensor. Maxon makes an example (rotary encoder) product (the MILE encoder).

Without scales Optical image sensor The sensors are based on an image correlation method. The Sensor takes subsequent pictures from the surface being measured and compares the images for displacement. Resolutions down to 1 nm are possible. Applications There are two main areas of application for linear encoders: Measurement Measurement application include (CMM), gear measurement, tension testers, and (DROs). Motion systems Servo controlled motion systems employ linear encoder so as to provide accurate, high-speed movement. Typical applications include, PCB assembly equipment; semiconductors handling and test equipment, printers and. Output signal formats Incremental signals Linear encoders can have analog or digital outputs.

The sine and cosine outputs. The industry standard, analog output for linear encoders is sine and cosine quadrature signals. These are usually transmitted so as to improve noise immunity.

An early industry standard was 12 µA peak-peak current signals but more recently this has been replaced with 1V peak to peak voltage signals. Compared to digital transmission, the analog signals' lower bandwidth helps to minimise emissions. Quadrature sine/cosine signals can be monitored easily by using an oscilloscope in XY mode to display a circular. Highest accuracy signals are obtained if the Lissajous Figure is circular (no gain or phase error) and perfectly centred. Modern encoder systems employ circuitry to trim these error mechanisms automatically. The overall accuracy of the linear encoder is a combination of the scale accuracy and errors introduced by the readhead. Scale contributions to the error budget include linearity and slope (scaling factor error).

Readhead error mechanisms are usually described as cyclic error or sub-divisional error (SDE) as they repeat every scale period. The largest contributor to readhead inaccuracy is signal offset, followed by signal imbalance (ellipticity) and phase error (the quadrature signals not being exactly 90° apart). Overall signal size does not affect encoder accuracy, however, signal-to-noise and jitter performance may degrade with smaller signals.

Automatic signal compensation mechanisms can include automatic offset compensation (AOC), automatic balance compensation (ABC) and automatic gain control (AGC). Phase is more difficult to compensate dynamically and is usually applied as one time compensation during installation or calibration. Other forms of inaccuracy include signal distortion (frequently harmonic distortion of the sine/cosine signals).

The A and B quadrature channels Many linear encoders interpolate the analogue sine/cosine signals in order to sub-divide the scale period, providing a higher measurement. The output of the interpolation process is quadrature squarewaves – the distance between edges of the two channels being the resolution of the encoder. The reference mark or index pulse will also be processed digitally and will be a pulse, usually one to four units-of-resolution wide. The major advantage of encoders with built-in interpolation and digital signal transmission is improved noise immunity. However, the high frequency, fast edge speed signals may produce more emc emissions. Incremental encoders with built-in digital processing make it possible to transmit position to any subsequent electronics such as a position counter. Absolute reference signals As well as analog or digital incremental output signals, linear encoders can provide absolute reference or positioning signals.

Reference mark Most incremental, linear encoders can produce an index or reference mark pulse providing a datum position along the scale for use at power-up or following a loss of power. This index signal must be able to identify position within one, unique period of the scale. The reference mark may comprise a single feature on the scale, an autocorrelator pattern (typically a ) or a pattern. Distance coded reference marks (DCRM) are placed onto the scale in a unique pattern allowing a minimal movement (typically moving past two reference marks) to define the readhead's position. Multiple, equally spaced reference marks may also be placed onto the scale such that following installation, the desired marker can either be selected - usually via a magnet or optically or unwanted ones deselected using labels or by being painted over.

Absolute code With suitably encoded scales (multitrack, digital code, or pseudo-random code) an encoder can determine its position without movement or needing to find a reference position. Such absolute encoders also communicate using serial communication protocols. Many of these are proprietary (e.g., Fanuc, Mitsubishi, FeeDat (Fagor Automation), EnDat, DriveCliq, Panasonic, Yaskawa) but open standards such as BiSS are now appearing, which avoid tying users to a particular supplier. Limit switches Many linear encoders include built-in limit switches; either optical or magnetic. Two are frequently included such that on power-up the controller can determine if the encoder is at an end-of-travel and in which direction to drive the axis. Physical arrangement and protection Linear encoders may be either enclosed or open.

Enclosed linear encoders are employed in dirty, hostile environments such as machine-tools. They typically comprise an aluminium extrusion enclosing a glass or metal scale. Flexible lip seals allow an internal, guided readhead to read the scale. Accuracy is limited due to the friction and hysteresis imposed by this mechanical arrangement.

For the highest accuracy, lowest measurement hysteresis and lowest friction applications, open linear encoders are used. Linear encoders may use transmissive (glass) or reflective scales, employing. Scale materials include chrome on glass, metal (stainless steel, gold plated steel, ), ceramics and plastics. The scale may be self-supporting, thermally mastered to the substrate (via adhesive or adhesive tape) or track mounted.

Track mounting may allow the scale to maintain its own and allows large equipment to be broken down for shipment. Encoder terms. //.

Index/reference mark/datum/. Distance coded reference marks (DCRM) See also. References. Understanding Encoders Motion Control Tips: A Design World Resource. Archived from on 2009-10-10. Retrieved 2009-10-30. Archived from (PDF) on 2013-11-03.

Retrieved 2011-11-15. Archived from on 2012-04-25. Retrieved 2011-11-02. Archived from (PDF) on 2011-10-13. Retrieved 2011-11-15.

Archived from on 2009-03-28. Retrieved 2009-10-28. Archived from on 2009-10-10. Retrieved 2009-10-29. Books. David S. Nyce: Linear Position Sensors: Theory and Application, New Jersey, John Wiley & Sons Inc.

Free Download Pdf Editor Software

(2003). Walcher Hans: Position Sensing: Angle and Distance Measurement for Engineers, Butterworth Heinemann (1994).